Commercial peptide production or synthesis is a chemical process that entails linking amino acids into a peptide chain. Although peptide production can occur naturally via in vitro heterologous expression systems or cell cultures, chemical synthesis has a higher throughput for industrial applications.

According to one literature review, the first application of chemical peptide synthesis was in the 1960s, when scientists first proposed using classical synthesis strategies. However, decades of practice helped refine the classical processes and set artificial peptide production as the backbone in multiple industrial and pharmaceutical applications. Therefore, keep reading to learn more about synthetic peptide production.

Artificial Peptide Synthesis is A Stepwise Process

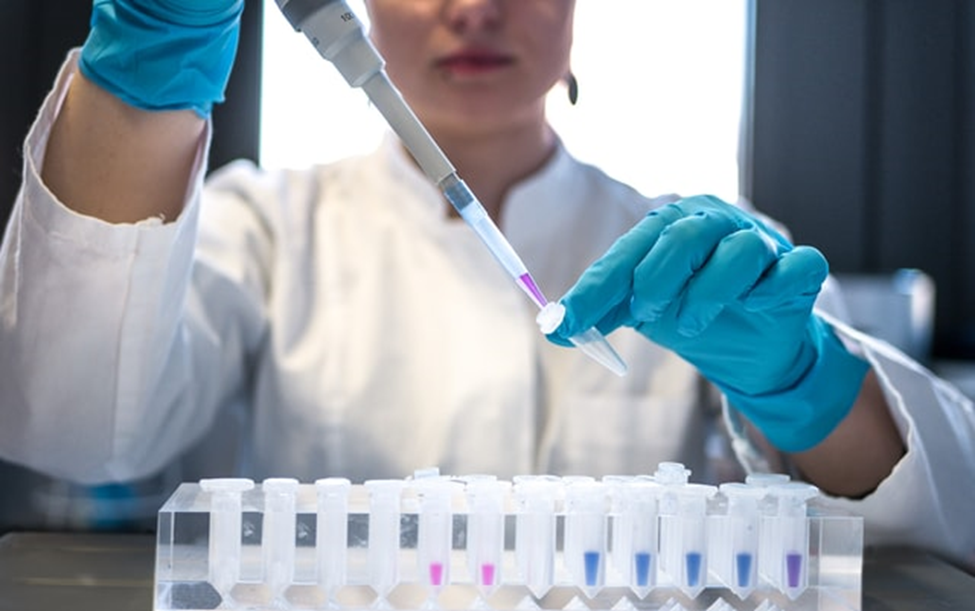

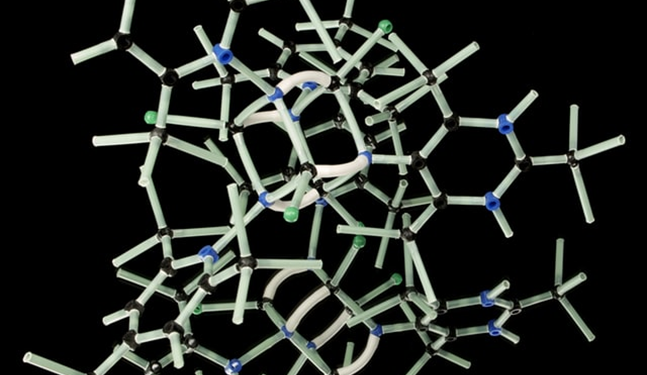

Amino acids are the building blocks for peptide synthesis, and binding two or more amino acids by creating peptide bonds is the primary concept behind the process. Creating peptide bonds is a three-step process including coupling, deprotection, and cleaving techniques.

You can learn more about each step of peptide synthesis. However, below is a quick overview of each step and its role in the invaluable peptide recombination process.

Coupling

A coupling reaction is an initial step in peptide elongation. It’s an organic chemistry reaction that forms a chemical bond between two organic molecules, amide or peptide bonds in this case.

The reaction kicks off after the chemists conducting the process add a coupling reagent to the resin with the target peptide. It begins from the Carboxyl terminal (C-terminal) and progresses towards the amine or amide terminal (N-terminus/terminal).

Commonly used coupling agents include BOP (benzotriazol-1-yloxytris (dimethylamino) phosphonium hexafluorophosphate), PyBOP, and HBTU (Hexafluorophosphate Benzotriazole Tetramethyl Uronium). Each coupling reagent has different properties that define its pros, cons, and suitability for specific peptide synthesis processes.

Base Deprotection

Racemization or non-targeted side reactions may occur during peptide synthesis; therefore, the addition of a protective group is vital to prevent reactions that may form side chains. The Fmoc protective group is the most popular protective group used during such reactions.

However, deprotection must occur to facilitate peptide bond formation, necessitating deprotection treatment. Therefore, a base labile is a vital compound that deprotects the amino acids by neutralizing the Fmoc base protecting group, stripping it from one molecule at a go.

Base deprotection facilitates the formation of high-quality peptide chains without undesirable side chains. The step focuses on removing protective groups on the base of the modifier.

Cleavage

Cleavage is the final step in protein synthesis and entails using acids of varying strengths, according to peptide property, to detach the newly formed peptide from the resin. You can learn more about the role of cleavage in various peptide synthesis strategies below.

Different Peptide Synthesis Strategies Are Available

Biotechnological advances contribute to different peptide synthesis strategy developments, including classical and contemporary techniques. Classical peptide synthesis techniques include liquid/ solution-phase synthesis (SPS), which was the premier strategy in the field.

You Can Read This Simler Article: taipei self-driving gharry

Peptide synthesis via SPS triggers the coupling between single amino acids attached to soluble solid support in a solution. However, individual molecule coupling means SPS takes too long, and the slow speed is among the primary reasons the strategy is becoming obsolete. Nonetheless, SPS is effective in synthesizing long-chain peptides by linking multiple short-chain peptides; moreover, it is also ideal for scalability.

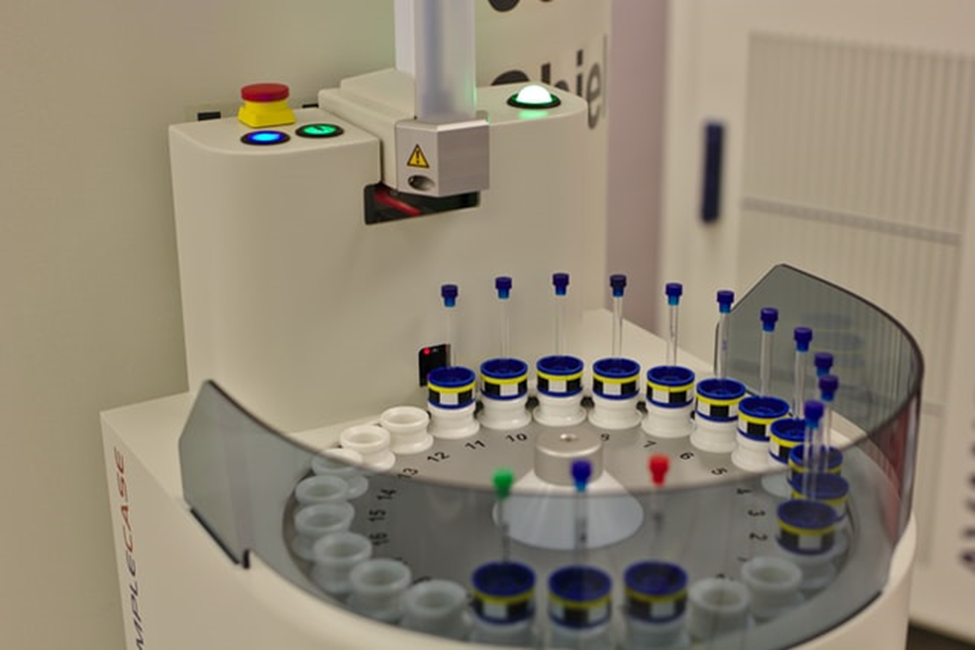

On the other hand, solid-phase peptide synthesis (SPPS) is the leading contemporary industrial chemical peptide production strategy. Unlike SPS, where a liquid is a synthesizing medium, SPPS entails attaching a peptide resin to insoluble polymeric support before adding a coupling agent.

SPPS has multiple advantages, including rapid linear peptide synthesis, simpler purification steps, higher yield, and high-quality peptide production. It is also efficient in generating non-native peptides featuring modified, non-native amino acids and post-translationally modified peptides. Therefore, its advantages explain its popularity among peptide synthesis service providers.

The Support And Linker Type Used Influences SPPS Results

The polymeric solid supports used during SPPS are primarily non-reactive; plenty of polymeric support options are available. However, their physical and chemical properties affect the overall peptide quality.

According to one literature review, specific solid supports have different loading capacities, and some cannot hold longer peptide chains, affecting overall PSSP performance. Second, the solid support also influences cleavage techniques, with some requiring a simple rinse and others an aqueous acid solution.

Third, other solid support materials promote legend binding while promoting non-specific adhesion. Therefore, optimized solid support surfaces improve the peptide synthesis progress.

Analytical Techniques Are Vital In Measuring Proper Peptide Composition

Chemical peptide synthesis is more effective in yielding high-quality peptides than heterologous expression systems. However, monitoring the process is necessary to ensure maximum yield and high quality.

First, researchers should monitor the deprotection process closely and counter any side reactions. Second, they also need to conduct analytical tests like high-performance liquid chromatography and mass spectrometry after peptide purification to ensure the target peptide is bioactive and functions as intended. Each analytical technique suits different peptide types, and service providers issue analytical certificates along with the synthesized peptides.

Peptide Customization Is Possible

Advances in peptide synthesis technology facilitate the production of non-native peptides. Such peptides may feature non-native amino acids or modifications to enhance their stability and efficacy. Techniques like covalent conjunction and amidation help improve a synthetic peptide’s stability and shelf life.

Conclusion

Peptide synthesis is gradually revolutionizing different industries by facilitating the creation of products that improve overall human wellbeing. Moreover, advanced peptide technology makes the process cheaper, and you can order custom or native peptides from an expert near you at affordable prices.

Also, Read The Following: your organization’s data cannot be pasted here

Discussion about this post